Excon 2019

Cellular lightweight concrete is one of the latest emerging technology in making the concrete. The CLC has many benefits over normal conventional concrete.

As we know the Fly Ash is the waste product of thermal power plant which cannot be easily disposed of. This solves the problem of disposal of fly ash and also reduces the cost of construction. The fly ash base CLC is environmentally friendly and it is produced with low energy.

The density of the fly ash based cellular lightweight concrete is lower than the normal concrete but the strength is the same. With this design, we can get a large number of bricks with less concrete.

The manufacturing process does not require any complicated techniques. The manufacturing process is the same as CLC and normal concrete just the foam generating machine is used.

This is the version of lightweight concrete which is produced like normal concrete with ambient conditions. It is manufactured by making a slurry of Cement + Sand + Fly Ash (26% – 34% content) + water.

The cellular concrete is a lightweight product having Portland cement, cement-silica, cement-pozzolan, lime-pozzolan, lime-silica pastes or pastes containing blends of these gradients with having a homogeneous void or cell structure and it is obtained by gas-forming chemicals or foaming agents.

The density in cellular lightweight concrete is controlled by gas or foam which is generated by foam generator.

CLC is an air-cured lightweight concrete with fly ash that is their main ingredient which can be produced at large projects sites like traditional concrete, utilizing equipment and molds used for traditional concreting.

It is suitable for places like India for low-rise load-bearing construction and for partitioning work in multi-story blocks.

Fly Ash is a new material for manufacturers. Fly Ash can have more than 25% (26% to 33%) of the total solid material constituents of CLC mixes for different density outputs.

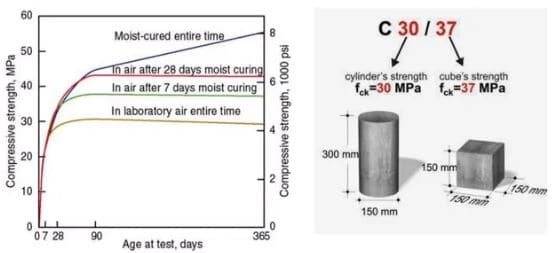

The Fly Ash is the waste product from the thermal power plants for over 25% constituent material. This CLC can be produced for a density range of 400 kg/m3 to 1800 kg/m3 with high insulation value and a 28-day cube crushing strength of up to 275 kg/cm2.

It is not only the waste material usage but also saves 40% of cement.

The density of the cellular lightweight concrete is 400 kg/m3 to 1800 kg/m3.

The benefit of Cellular Lightweight Concrete is fireproof, termite-proof, thermally insulated, soundproof, environment-friendly.

The CLC has a wide range of densities like 400 kg/m3 to 1800 kg/m3 for different applications.

Lower densities like 400-600 kg/m3 are suitable for thermal insulation applications. It is the fire, termite, water-proof-ness, termite-resistance, and very low water absorption and it is environmental friendliness. It is also used in laying sound-insulating layers for structural slabs for intermediate floors for high-class hotel buildings for minimizing noise between lower and upper floors. This is also used for filling depressions in bathrooms or other floors etc. It is a very good alternative to Thermocole, glass wool, wood wool, etc.

The medium density of 800-1000kg/m3 is used for pre-cast blocks for non-load-bearing walling masonry in framed structures. The size of the block is 500x250x200 mm and internal partition blocks are 500x250x100 mm. Also, it can be manufactured in the desired size.

The high-density range is 1200 kg/m3 (crushing strength 65 kg/cm2) to 1800 kg/m3 (crushing strength 250 kg/cm2) is grade material used for:

The in-site casting of structural walls and roofs of low-rise individual or group housing schemes.

It is used for reinforced structural cladding or partitioning panels.

For making pre-cast blocks (500x250x200/100 mm) for load-bearing walling masonry for low rise buildings.

It has properties like

Low weight

Good fire resistance

Thermal insulation

Thermal expansion is negligible

No Freezing and thawing

Sound absorption

Less tendency to spall.

It is used for the construction of partition walls.

Partitions for heat insulation purpose.

Construction of hollow filled floors.

The reinforced concrete is a combination of traditional cement concrete with reinforcements (steel bars). The combination is made to utilize the compressive strength of concrete and tensile strength of steel at the same time to provide maximum strength. The meaning of reinforced is the steel reinforces the concrete and makes it stronger construction material.

The reinforced concrete needs to be specially engineered. If the amount of the reinforced is not enough the concrete can be weak or may have a failure. With many advantages, the reinforced concrete has disadvantages too. The reinforced concrete can be molded and shaped which is a limitation for other materials and also give freedom to create innovative designs.

The reinforced concrete is very popular building material having characteristics like strong, easy to work with, adaptable, versatile, durable and affordable. It is mainly used in the construction of foundations of rooftops of the building, highway construction, precast structures, floating structures, hydro-power tunnels, irrigation canals, drain, and all other conceivable structures.

Strength

It has very good strength in tension as well as compression which makes it one of the best construction materials.

Economical

The concrete constituents are widely available worldwide and also inexpensive. Also, the production cost is very low. It is widely used as the reinforced concrete has less maintenance cost as it has a long-lasting nature of reinforced concrete.

Reinforced concrete has durability, resilience, required low maintenance and energy-efficient. The concrete structures reduce the operating cost of operational energy consumption.

Versatility

The concrete can be placed into various shapes if shuttering or formwork configuration to form desired shapes, form, surface, texture and sizes at the construction site. The concrete is in liquid form when it made which is more suitable for many architectural requirements.

Durability

The reinforced concrete structures are durable. It is having no effect of rainfall, snow and can last up to 100 years.

As concrete has low permeability it can resist chemicals that dissolve in water like sulfates, chloride and carbon dioxide and all these cause corrosions in concrete without serious deterioration.

These make reinforced concrete more suitable for underwater submerged applications like pipelines, dams, canals, linings and other waterfront structures.

Fire Resistance

The concrete does not catch fire or burn. It can be withstanding heat for 2 to 6 hours for rescue operations in a fire. The reinforced concrete buildings are more fire-resistant than other construction materials like steel and wood. The reinforced concrete is suitable for fireproof steel and high-temperature applications.

Ductility

The steel provides ductility to the reinforced concrete structures. The ductility in concrete shows the distress in cracking and deflection if the reinforced concrete having the overloading. This enables the engineers to consider engineers to save it from concrete damages.

Seismic Resistance

It is properly designed for reinforced concrete structures that are resistant to earthquakes.

Ease of Construction

As compared with the steel used in the structure, reinforced concrete requires less skilled labor for the erection of the structure.

There are several industrial wastes and by-products like fly ash, slag known as GGBFS or ground granulated blast-furnaces slag, waste glass and like the ground, tires can be recycled as a substitute for cement or aggregate or supplementary materials. The concrete production reduces environmental impacts due to industrial waste and also improves the characteristics of concrete and consequently, the quality of the structure is not compromised.

The concrete can be recycled as aggregate for the use as sub-base material in roadbeds and parking lots, gabion walls as riprap to protect shorelines or in other applications or granular material with reducing the amount of material which is landfilled and need for virgin materials in new construction.

One of the main advantages of concrete is its ability to use different application methods. Concrete is also hand-applied, poured, pumped, sprayed, grouted and it is also used for application for shotcrete and tunnels.

The fly ash bricks manufacturing business is more and more profitable and fastest-growing business in India. The people in India is started using the Fly Ash Bricks to save earth for the future. There is also a reason for the ban of red clay bricks in some of the states.

Here are some tips that need to be considered before starting of fly ash manufacturing process.

To start a fly ash brick manufacturing business required a minimum a half-acre of land. It is suggested that one-acre land is enough for stock and curing the bricks.

Find the location which is near to the 100 km radius of Thermal Power Plant to easily get the fly ash quota from EB.

The fly ash bricks manufacturing process required lots of water. So it is advisable to establish a factory where the freshwater is easily available.

Fly ash required special care while unloading in open space as it is dangerous to the atmosphere. The factory should be not in a residential area as the micro dust particles are harmful to the surrounded people.

Some are using Silos to store fly ash. As it is not necessary for everyone.

The project cost includes plant, machinery and working capital is approximately 30,00,000 Rs. This estimation is based on machinery with the production of 12,000 bricks per shift. (The Diesel power generator is not included).

The cement manufacturers have installed giant silo’s in thermal power plant to collect the fly ash. They get the majority share of fly ash from thermal power plants. Fly Ash manufacturers have to struggle to get the fly ash.

If you want to run your business successfully you required labour. As the work with fly ash, there is somewhat dusty so it is hard to get suitable labours. You can attract labours with high pay and also give some incentives.

The profit is varying from place to place. But in this business, you will definitely make 1 Rs. per brick as profit.

Your profit is depending on the availability of raw material, labour, power supply.

If you want to succeed in your business, is dependent on the availability of fly ash from the thermal power plant.

If you planning to start a fly ash manufacturing business do proper research for where and how much you can get fly ash. One source is to bought fly ash from the black market, so it is advised to get your fly ash quota to continue to making fly ash bricks.

In the process of fly ash bricks, machine required regular maintenance and tune-ups. This service is only provided by experts who have long experience in this field. The new machine manufacturers give discounts but the machines are not sustainable.

The rotary type hydraulic machines are recommended for new entrepreneurs as it is cost-effective.

Here we are talking about what is prestressed concrete and why it is widely used these days. We will also see the advantages and where the prestressed concrete is used.

The prestressed concrete has the ability to eliminate the traction forces of the concrete by adding artificial compression tensions before applying exterior loads. And also assure that when it is superimposed, the total permanent tensions should lie between the limits which the material can bear indefinitely. This technique is widely used in modern days to building all the architectural and engineering projects. As this method has many benefits.

There are many advantages of using prestressed concrete which is given below.

With the use of the prestressed technique in concrete gives the maximum strength by providing an internal compression force which counteracts the traction force produced by loads of the structural elements.

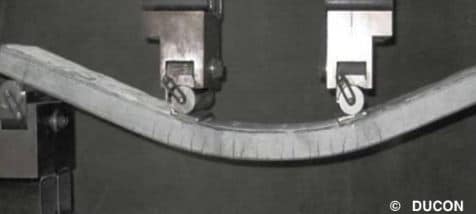

One of the principal benefits of the prestressed beams is it eliminates the crack from all the load stages. There is no crack which means the structure has a greater capacity to withstand loads, impacts, vibration and knocks and minimize the possibility the corrosion in steel which increases the durability of the construction.

The tensile concrete allows using of large spans in construction due to the length of pieces which saves material and it is light in weight also. These tensile prestressed beams are using in places like an industrial warehouse which provide better light. It is also used in car parks as these plates allow greater separation. Between loading columns and resulting in saving of material and have large space.

These pieces are easier to use to make any beautiful architectural elements.

The large-scale production of prestressed beams and hollow core slabs provide quality control. High production and minimum production cost which very helps full for large architectural buildings and other projects.

The construction speed is increased by using prestressed concrete. As the many parts of the building can assemble at the same time. And this helps both economically and also save time.

Here we provide information about fly ash bricks composition. We describe a process with which material you can manufacture fly ash bricks in less price. The fly ash bricks are made with mainly three different mixing ratios. The price of brick is mainly depending on which fly ash bricks mixing ratio is used.

The cost of fly ash bricks is depending on which composition is used. But whatever fly ash bricks mixing ratio is used and along with that, you have to maintain the quality too.

You can make quality bricks with using best mixing ratio and raw materials as per market requirements. Business is about how to increase profit by using the proper mixing ratio to manufacture fly ash brick at a low cost. Here we explain the 3 very trusted and proven mixing ratios to manufacture fly ash bricks.

The material is used to manufacture a fly ash brick is depend on raw material availability and requirement of bricks. It is suggested to use Sludge Lime as it is less expensive than Hydrated Lime. The above mixing ratio is more profitable mixing ratio than below two. The Sludge lime is waste material and costs less than hydrated lime. Sludge lime is usually wet and has lumps and it is used to make quality fly ash bricks.

Here Hydrated lime is used instead of Sludge lime.

This mixing ratio is widely used to make quality fly ash bricks. As hydrated lime is easily available this fly ash brick compositions are used by many fly ash brick manufacturers.

In this mixing ratio, the cement is used instead of gypsum and lime. This ratio is not so used because it is costly and not preferred by entrepreneurs. The price of cement is more than gypsum and lime; thus, this mixing is used only when gypsum and lime are not available.

We Q Green Techon PVT LTD. Provide best quality fly ash making machines in India. Our machines are equipped with the latest technology to manufacture a maximum number of fly ash bricks. We have different types of fly ash making machines having various manufacturing capacity. We provide service both on-site and overcall also.

The fly ash bricks are used more and more these days in brick masonry structures. The fly ash bricks are higher in quality and made with advanced technology. It is used as the replacement of normal clay bricks and it is better than it.

With the use of fly ash brick than normal clay bricks have many benefits. The main benefit of using fly ash bricks is we can save natural resources and also protect the environment.

India’s 72 percent power plants are coal based and these plants produce 40 million ton fly ash annually. The fly ash contains Co2 which is emitted from thermal power plants and industries which used coal as fuel and emits ash and smoke and from it the fly ash is made. The power plants and industries use cyclone converters to separate fly ash and this fly ash is used as raw material for making fly ash bricks.

The fly ash cause more environmental problems include air, water and also land. It required proper management to control pollution caused by fly ash and there for using fly ash to make various products and save the environment.

The fly ash brick is a slow setting pozzalona cement mix. The process is almost identical to make cement where the clay and limestone are burnt with coal and gypsum and then mixed.

In fly ash brick making the burnt clay particle obtain from burning the coal. When the hydrated lime powder, gypsum is mixed in a pan, the mixture starting turns slowly in pozzalona cement.

The mixture is pressed in the low pressure in low moisture in hydraulic machine and the machine is specially designed to give the high pressure at a slow rate and the pressure is 350kg/square inch.

The required pressure and holding the bricks for particular time gives maximum strength to fly ash bricks.

The emission of greenhouse gases is increasing more and more nowadays and the Co2 is a major one. The total CO2 emission was 24,960 million tons count globally in 1990.

In India, the CO2 emissions from the cement industry are ninety million tons and forty-nine tons from clay brick manufacturing. As per current statics for producing one million brick required 200 tons of coal and this coal emits around 270 tons of CO2 in the air.

The Fly Ash brick production is totally emission free and the manufacturing process is qualified under Clean Development Mechanism (CDM).

| Properties | Red Brick/Clay Brick | Fly Ash Brick | Remark |

| Density | 1600-1700 kg/m3 | 1700-1850 kg/m3 | Higher Load Bearing |

| Compressive Strength | 30-35 kg/cm2 | 90-100 kg/cm2 | Higher Load Bearing |

| Absorption | 15-25% | 10-14% | Less dampness |

| Dimensional Stability | Very low tolerance | High tolerance | Saving in mortar up to 25% |

| Wastage during transit | Up to 10% | Less than 2% | Saving cost up to 8% |

| Plastering | Thickness varies on both sides of the wall | Even on both sides | Saving in plaster up to 15% |

Before starting the discussion on fly ash bricks first, we have to look at the effect of red clay bricks on nature.

There is one estimate that around 180 billion tonnes of common burnt bricks are used per annum which means it required 340 tonnes of clay and it comes from the top layer of around 5000 acres of land dug out by brick manufacturers. The red clay brick is heated and required coal or wood which may the cause for deforestation.

The pulverized fuel ash is generally known as fly ash and it is a by-product from the coal-based power plant. The fly ash brick manufacturer uses this ash to make the fly ash brick as the alternative of red clay bricks.

The demand for fly ash bricks in India is increasing. As the cost and environmental benefits, people prefer more and more fly ash bricks over common burnt bricks.

India depends on the coal-based power plant. These plants produce a very large amount of fly ash. The government has no other way to dump the fly ash and the fly ash is dangerous for the environment.

The fly ash brick making is a very profitable business in India as the brick quality is high and required less resource than common burnt bricks.

First, it required a minimum half acre of land prefer 1 acre for storing and curing the bricks.

Second, choose the factory location in 100 km radius of the thermal power plant to get permission and quota of fly ash. For make fly ash brick required lots of water. So make sure that you have enough water supplies to continue the production.

One of the problems to make fly ash brick is to store fly ash. You could not store fly ash in open ground as it is harmful. So it is advisable to store in Silo.

To make fly ash bricks required approximately 30, 00,000 INR as working capital. This includes machinery and production capacity of 12,000 bricks per shift.

In growing India labor is the biggest problem and the fly ash brick making is not an easy task and somewhat dusty work. So attract the labors with high pay and incentives.

The profit factor is very high in the fly ash brick manufacturing. There is a minimum profit of 1 INR per brick is for sure. It may vary for different places and it depends on labour, raw materials and power supply.

As we know the fly ash is only available through the thermal power plant. So before starting business manufacturers have to research on demand for fly ash bricks and the availability of fly ash. It is advisable to get your quota of fly ash than to buy from the black market.

Machinery is a heart of any industry. So buy a machine from the well-established manufacturer. The reason behind is this machine required regular tune-ups and frequent maintenance in the starting of production. The rotary type hydraulic machine is highly recommended for primary manufacturers.

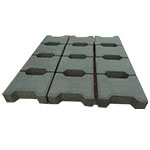

Q Green specializes in the production of vibration-based machines for block and pavers. We have supplied more than 55 Q Green paver block making machines throughout the country that help manufacture superior quality paver blocks. It is used in various government and domestic applications. It comes in different variants, shapes and sizes but usually, for government projects, we use 80 mm paver blocks. The main application of it is in building internal roads. The strength required for this is m40 with a 12% cement percentage. But it is to be mentioned that the use of Q Green machines is not only limited to this alone.

Using vibration technology usually makes paver blocks. There are some advantages of purchasing our products that have already been mentioned in our previous articles.

Some specific benefits of the paver block making machine have been listed for your convenience.

Q Green’s paver block making machine start from the initial cost of Rs. 40 lakh and have many variations like 12 pavers at a stroke, 15 pavers at a stroke and the like.

The models that we have are RT4, RT6, RT9 and RT15 that comes with all kinds of automation (semi and fully automatic line).

In case of any query, you can leave a query on our official website.

For any fly ash brick machine, Inquiry Call Us Now: +91 97320 35946 or Mail Us: [email protected]

Also Visit Our Site: www.qgreentech.com

It is a pleasure to inform all our readers that we are participating in the Concrete Show, Mumbai from 24th May 2018 – 26th May 2018. This is the sixth edition of the show and it has seen a phenomenal response in each of them. Concrete Show is an extremely comprehensive event and we are honoured to be a part of it.

It is a mega event of the state of Maharashtra and is a forum that witnesses participation from all over the world. There are about 133 exhibitors this year and we are expecting a visitor count of over 50,000.

We have participated in all major events around the globe and this is our 5th year in association with the Concrete Show. We look forward to seeing you in the Show and discussing productive future prospects.

Venue: Concrete Show, Bombay Exhibition Centre, Goregaon, Mumbai

Stall number: E-32