Fly Ash Cellular Lightweight Concrete Properties and Uses

Cellular lightweight concrete is one of the latest emerging technology in making the concrete. The CLC has many benefits over normal conventional concrete.

As we know the Fly Ash is the waste product of thermal power plant which cannot be easily disposed of. This solves the problem of disposal of fly ash and also reduces the cost of construction. The fly ash base CLC is environmentally friendly and it is produced with low energy.

The density of the fly ash based cellular lightweight concrete is lower than the normal concrete but the strength is the same. With this design, we can get a large number of bricks with less concrete.

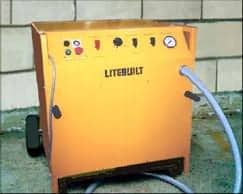

The manufacturing process does not require any complicated techniques. The manufacturing process is the same as CLC and normal concrete just the foam generating machine is used.

Fly Ash Cellular Lightweight Concrete

This is the version of lightweight concrete which is produced like normal concrete with ambient conditions. It is manufactured by making a slurry of Cement + Sand + Fly Ash (26% – 34% content) + water.

The cellular concrete is a lightweight product having Portland cement, cement-silica, cement-pozzolan, lime-pozzolan, lime-silica pastes or pastes containing blends of these gradients with having a homogeneous void or cell structure and it is obtained by gas-forming chemicals or foaming agents.

The density in cellular lightweight concrete is controlled by gas or foam which is generated by foam generator.

CLC is an air-cured lightweight concrete with fly ash that is their main ingredient which can be produced at large projects sites like traditional concrete, utilizing equipment and molds used for traditional concreting.

It is suitable for places like India for low-rise load-bearing construction and for partitioning work in multi-story blocks.

Fly Ash is a new material for manufacturers. Fly Ash can have more than 25% (26% to 33%) of the total solid material constituents of CLC mixes for different density outputs.

The Fly Ash is the waste product from the thermal power plants for over 25% constituent material. This CLC can be produced for a density range of 400 kg/m3 to 1800 kg/m3 with high insulation value and a 28-day cube crushing strength of up to 275 kg/cm2.

It is not only the waste material usage but also saves 40% of cement.

The density of the cellular lightweight concrete is 400 kg/m3 to 1800 kg/m3.

The benefit of Cellular Lightweight Concrete is fireproof, termite-proof, thermally insulated, soundproof, environment-friendly.

Cellular Lightweight Concrete – Density Range

The CLC has a wide range of densities like 400 kg/m3 to 1800 kg/m3 for different applications.

Lower densities like 400-600 kg/m3 are suitable for thermal insulation applications. It is the fire, termite, water-proof-ness, termite-resistance, and very low water absorption and it is environmental friendliness. It is also used in laying sound-insulating layers for structural slabs for intermediate floors for high-class hotel buildings for minimizing noise between lower and upper floors. This is also used for filling depressions in bathrooms or other floors etc. It is a very good alternative to Thermocole, glass wool, wood wool, etc.

The medium density of 800-1000kg/m3 is used for pre-cast blocks for non-load-bearing walling masonry in framed structures. The size of the block is 500x250x200 mm and internal partition blocks are 500x250x100 mm. Also, it can be manufactured in the desired size.

The high-density range is 1200 kg/m3 (crushing strength 65 kg/cm2) to 1800 kg/m3 (crushing strength 250 kg/cm2) is grade material used for:

The in-site casting of structural walls and roofs of low-rise individual or group housing schemes.

It is used for reinforced structural cladding or partitioning panels.

For making pre-cast blocks (500x250x200/100 mm) for load-bearing walling masonry for low rise buildings.

Properties of CLC

It has properties like

Low weight

Good fire resistance

Thermal insulation

Thermal expansion is negligible

No Freezing and thawing

Sound absorption

Less tendency to spall.

Use of the CLC

It is used for the construction of partition walls.

Partitions for heat insulation purpose.

Construction of hollow filled floors.