Normal Concrete vs High-Strength Concrete Properties and Differences

Concrete is used as construction material and it is categorized as normal concrete or high strength concrete based on its compressive strength. The compressive strength of normal concrete is between 20 and 40 MPa. The strength of high strength concrete is above 40 MPa.

The high strength concrete has compressive strength between 40 and 140 MPa which is discussed in this article.

As time goes the difference between normal and high strength concrete also changes. 100 years ago the concrete having a compressive strength of 28 MPa was considered as high strength concrete. Now the concrete can get strength greater than 800 MPa and is called reactive powder concrete.

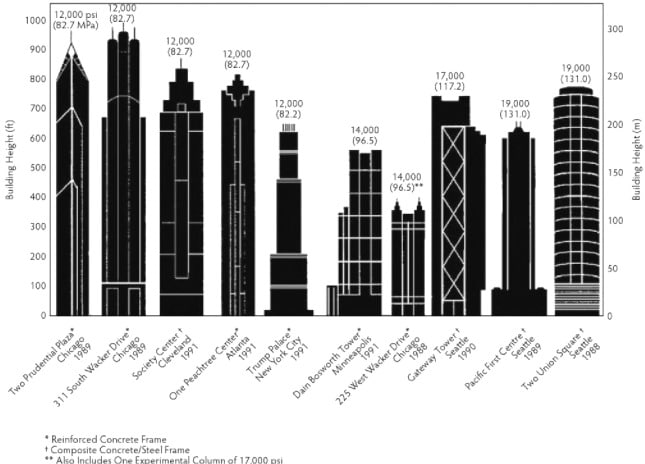

When we talk about the application the normal strength concrete is widely used compared to high strength concrete. The main benefit of high strength concrete is for reducing weight, creep or the permeability issues, for improving the durability of the structure and for special architectural requirements were elements carry smaller loads.

What are the properties of Normal and High Strength Concrete?

Whether it is normal or high strength concrete, it should be mixed having the nature of plastic or semi-fluid that it can mold by hand or by using mechanically.

It is very important that the mixture does not go through bleeding or segregation in handling or transportation. The uniform distribution of aggregates helps the concrete to control the segregation.

Workability factors of Normal and High strength Concrete

The workability factor is the ease where the concrete is placed, compact and finished in its fresh state.

The normal strength concrete possesses having good workability that all concrete ingredients are in proper and accurate proportions. These aggregates must be of a proper gradation.

The high strength concrete mix is often sticky and also found difficult to be handled and placed. This is even if the plasticizes are used. It is due to high cement content in it.

Bleeding Factors for Normal and High Strength Concrete

The bleeding is the settlement of solid particles of cement and the aggregate in the fresh concrete mix which results in the development of a layer of water on the top of the concrete surface. The smaller bleeding does not make any issue but the large-scale bleeding affects the durability and strength of the concrete.

When we compared the normal and hard strength concrete the high strength concrete does not bleed. Which is because the high strength concrete has smaller water content and a high amount of cementitious materials. The air-entrained concrete also has fewer chances to bleed.

Permeability of Normal and High Strength Concrete

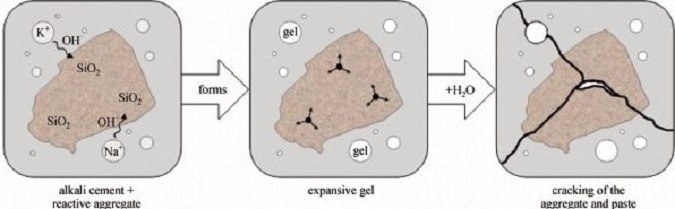

The durability problems like corrosion resistance, chemical and creep have a direct relationship with the permeability of the concrete. If the foreign substance enters inside the concrete the damage occurs. It depends on the permeability property and the paste and aggregates present in the concrete.

The decrease in permeability beneficial in

- Improves sulfate and chemical attack resistance

- Resistance to corrosion

- Resistance to chloride penetration

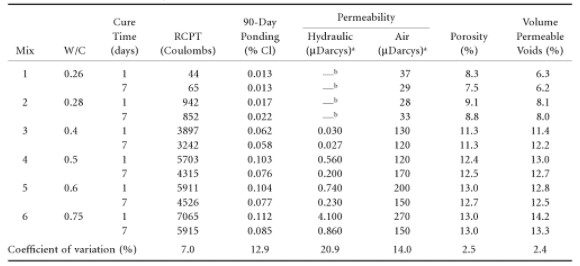

The below table shows the test results of various permeability tests conducted on the different concrete mixes. The table also provides information on normal strength concrete and high strength concrete in water and cement ratio.

The lower water-cement ratio with an adequate curing period helps in having a concrete of lower permeability. For the normal strength concrete, the permeability is found to be in the range of 1 x 10 -10 cm/sec.

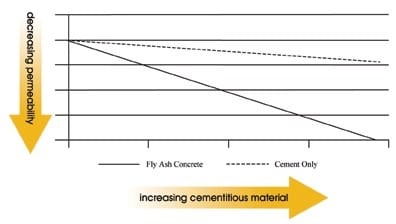

The additional cementitious materials added in the concrete mix like silica fume, fly ash and GGBFS helps to reduce the permeability of the concrete.

High strength concrete has a lower value of permeability compared to normal strength concrete. which is because the high-strength concrete is designed with a lower water-cement ratio. The silica fume is commonly used in the mix. The high strength concrete has permeability ranges from 1 x 10 -11 to 1 x 10-13 cm/sec.

The high strength concrete has low permeability and high resistance to chloride attack which makes it suitable for bridge construction, parking decks and structures are exposed to seawater.

Carbonation of Normal Strength Concrete and High Strength Concrete

The carbonation happens on the surface of the concrete. the carbonation is related to the permeability of the concrete. carbon dioxide of the air reacts with the compounds present in hardened cement paste. This reaction is called calcium carbonates.

The effect of carbonation is mentioned in the permeability factor is less in high strength concrete compared with normal strength concrete.

In both types of concrete mix, the essential amount of protective concrete covers the reinforcement steel which reduces the easy reach to the reinforcement.

Difference between Normal Strength Concrete and High Strength Concrete

The normal strength at 40% of compressive strength value the micro-cracks are formed. These interconnects and propagates reaches 80 to 90% of the strength.

In the normal strength concrete, the fracture surface is very rough. This zone is formed along with the transition zone between the paste matrix and aggregates. The fracture surface in high strength concrete is smooth.