With the given research and development, there are two technologies to manufacture fly ash bricks. These are commonly used to make bricks, blocks, pavers and all related products.

The first one is the hydraulic system. The bricks are produced using a hydraulic cylinder and the raw material is compressed in a steel mould. This is suitable for raw material with higher powder content. This is the reason why it is also known as the powder compacting technology. With this technology, we usually do not use a raw material with a size more than -5 mm. This is good for manufacturing fly ash bricks making production possible with a small budget as well. In Q Green Techcon Pvt. Ltd, we make hydraulic fly ash brick making machine starting from Rs. 13 lakhs. Looking at the labour issues, we have introduced automation in these hydraulic fly ash brick making machines where the labour will be limited to 5-6 in number. Not only that, we are also providing a batching plant in the machines if the customer wants to make 15000 fly ash bricks or more exclusively. We also have QGH25 Twin, which allows us to feed two systems with a single batching plant. We have a model, QGH Smart that is extremely suitable for those who have a low budget but are looking for production of about 7000 bricks per 8 hours. We also have QGH 17, with a production of 10,000 fly ash bricks per 8 hours and is available at Rs. 18.5 lakh. This machine is very popular as it suits the market very well. We also have QGH 25, which has been incorporated with certain automation, subject to the labour issues in the country. For example, we have incorporated mixer automation (water automation and gate opening automation). Apart from this, we have many other fly ash brick making machines the details of which will be available on request.

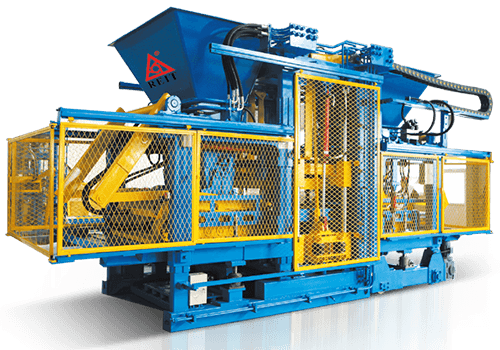

The second technology that can be used in the production of fly ash bricks is the vibration technology. This can make concrete products but we have further devised it with greater and better innovations. We have ensured that the same machine can make concrete products like paver, blocks and hollow blocks and will also enable you to produce bricks, with or without using fly ash. Many machines have a timer-based vibration, which leads to settling of the larger particles in the bottom. In Q-Green, we use variable vibration that prevents this and hence makes stronger bricks that are of superior quality. Further, in a Vibro machine, the number of bricks that can be produced is large. Each brick is vibrated with the same intensity and is most suitable for concrete. Since it is big board, it is possible to go to full automation lowering the necessity and requirement of labour in the brick making process. For example, when one needs to work on a 50000 project, it requires 20-22 bricks per stroke. This is not possible in a hydraulic machine nor is it economically viable in the same. Hence, in a vibration technology machine, the production is more and it has an edge as far as the economic viability of the introduction of a handling system is concerned. We do provide vibro machines as well. We have established a venture with REIT, a pioneer in this technology based in China. They have patents of various technologies making us the best in the market. We have started the production of these in India, too.

Q-Green Techcon Pvt. Ltd does provide both variants of brick making machines and has a range that is suitable for all product budgets and ranges. We have seen an overwhelming response in India and hope to innovate and build as we move forward.

For any fly ash brick machine, Inquiry Call Us Now: +91 97320 35946 or Mail Us: [email protected]

Also Visit Our Site: www.qgreentech.com