What is Cellular Concrete?

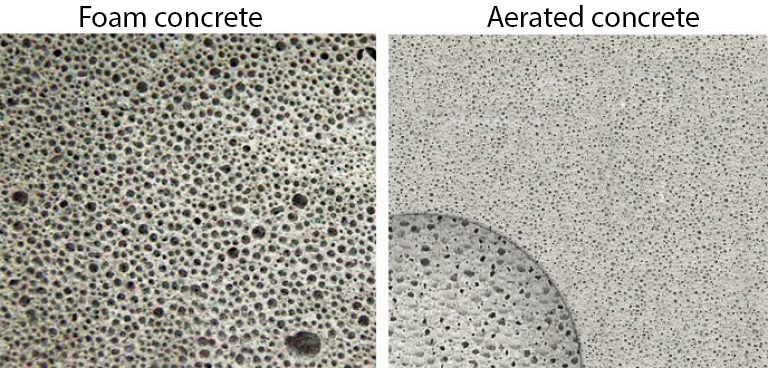

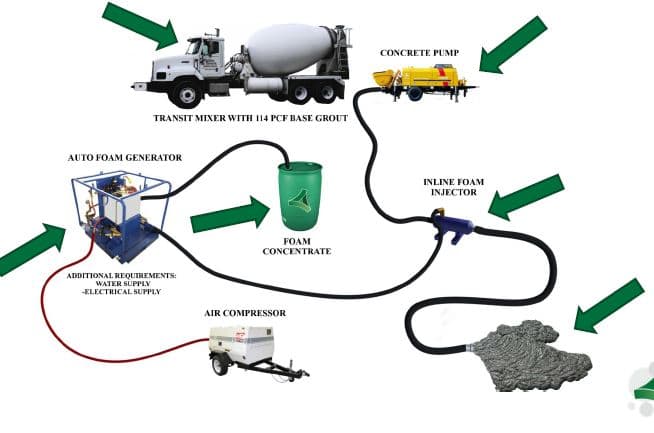

The cellular cement is a specially engineered concrete manufactured by mixing the Portland cement, sand, fly ash, water, and pre-formed foam in various proportions to form a hardened material having an oven-dry density of 50 pounds per cubic foot (PCF) or less.

As per the definition by ACI, the density of cellular concrete must be lesser than 50 pounds per cubic foot. The cellular concrete has a density of 20 PCF to 120 PCF.

The important characteristic of cellular concrete is its self-compacting property where no compaction is required the concrete flows from the pump to fill the mold. With this property, it can be pumped for long-distance and height.

The specially engineered concrete is also known as foam cement, foamed concrete or lightweight flow-able fill.

Which types of material used in Cellular Concrete?

Cement

The cellular lightweight concrete is a homogeneous combination of Portland cement, cement-silica, cement-pozzolana, lime-pozzolana; lime-silica pastes with having of identical cell structure obtained from gas-forming chemicals or foaming agents at measured levels.

Fly Ash

Fly ash is a by-product of thermal powerplant and its disposal be very expensive. The fly ash is used in the manufacturing of light-weight concrete. fly ash is a key ingredient and at the same time, the disposal problem is also solved.

Foam

In the raw material the foam is used and in the making of cellular concrete is Genfil and its organic substance. The size of the bubbles has differed from o.1 to 1.5 mm in diameter. The foam generator is used to make stable foam using an appropriate agent.

Reference codes of Cellular Concrete

ASTM C 869 – standard specification for Foaming Agents Used in Making Preformed Foam for Cellular Concrete.

The ASTM C 796 – standard test method for foaming agents for use in producing cellular concrete using preformed foam.

ASTM C 495 – standard test method for compressive strength of lightweight insulating concrete.

Types of Cellular Concrete (Density vise)

The cellular concrete is divided into 3 types based on density.

High-Density Cellular Concrete

This is a structural grade concrete having a density of 1200 k/m3 to 1800 kg/m3 and it is used in the construction of load-bearing walls, partition walls and in the production of pre-cast blocks for load-bearing brickwork.

Medium Density Cellular Concrete

The density range is 800-1000 kg/m3. It is mainly used in the manufacturing of pre-cast blocks for non-load-bearing brickwork.

Light Density Cellular Concrete

Light density cellular concrete has a density range of 4—600 kg/m3. The LDCC is ideal for thermal and sound insulations. It is mostly fired resistance, termite and moisture absorbent. It is also used instead of glass wool, wool wool, and thermocol.

Advantage of Cellular Concrete

Lightweight

Having the lightweight is advantageous for building dead loads and craning works.

Fire Resistance

The air pocket in the concrete works as a barrier for fire. The structure made with cellular concrete is non-combustible and can endure fire breakout for hours.

Thermal Insulation

Cellular concrete is a perfect thermal insulator.

Acoustical Insulation

The low density increases acoustical insulation.

Environment-Friendly

Fly-ash based CLC is suitable to use as the fly-ash is the by-product of the thermal power plant.

Cost-Efficient

The cost of the raw material is used in the concrete is decreased as the foam is used in the concrete. The use of waste of thermal plant-like fly ash saves money invested for cement products.

Other Advantage

The cellular light-weight concrete is termite-proof and resistant to freezing issues.

Where are the Cellular Concrete is used?

- The cellular lightweight concrete is used as thermal insulation in the form of bricks and blocks over flat roofs or non-loading walls.

- Bulk filling by applying relatively low strength material for old sewer pipes, wells, unused cellars and basements, storage tanks, tunnels, and subways.

- Production for heat-insulated light wall panel.

- Maintain an Acoustical balance of concrete.

- Manufacture cement and plaster-based light plate.

- For the production of special light heat-resistant ceramic tiles.

- For the soil water drainage purposes.

- Used in the bridge to prevent freezing.

- Used in tunnels and shaft filling and lightweight concrete manufacturing.

- Production in Perlite plaster and Perlite lightweight concrete.