What is Reinforced Concrete? It’s Uses, Benefits & Advantages

The reinforced concrete is a combination of traditional cement concrete with reinforcements (steel bars). The combination is made to utilize the compressive strength of concrete and tensile strength of steel at the same time to provide maximum strength. The meaning of reinforced is the steel reinforces the concrete and makes it stronger construction material.

The reinforced concrete needs to be specially engineered. If the amount of the reinforced is not enough the concrete can be weak or may have a failure. With many advantages, the reinforced concrete has disadvantages too. The reinforced concrete can be molded and shaped which is a limitation for other materials and also give freedom to create innovative designs.

The reinforced concrete is very popular building material having characteristics like strong, easy to work with, adaptable, versatile, durable and affordable. It is mainly used in the construction of foundations of rooftops of the building, highway construction, precast structures, floating structures, hydro-power tunnels, irrigation canals, drain, and all other conceivable structures.

Advantages of Reinforced Concrete

Strength

It has very good strength in tension as well as compression which makes it one of the best construction materials.

Economical

The concrete constituents are widely available worldwide and also inexpensive. Also, the production cost is very low. It is widely used as the reinforced concrete has less maintenance cost as it has a long-lasting nature of reinforced concrete.

Reinforced concrete has durability, resilience, required low maintenance and energy-efficient. The concrete structures reduce the operating cost of operational energy consumption.

Versatility

The concrete can be placed into various shapes if shuttering or formwork configuration to form desired shapes, form, surface, texture and sizes at the construction site. The concrete is in liquid form when it made which is more suitable for many architectural requirements.

Durability

The reinforced concrete structures are durable. It is having no effect of rainfall, snow and can last up to 100 years.

As concrete has low permeability it can resist chemicals that dissolve in water like sulfates, chloride and carbon dioxide and all these cause corrosions in concrete without serious deterioration.

These make reinforced concrete more suitable for underwater submerged applications like pipelines, dams, canals, linings and other waterfront structures.

Fire Resistance

The concrete does not catch fire or burn. It can be withstanding heat for 2 to 6 hours for rescue operations in a fire. The reinforced concrete buildings are more fire-resistant than other construction materials like steel and wood. The reinforced concrete is suitable for fireproof steel and high-temperature applications.

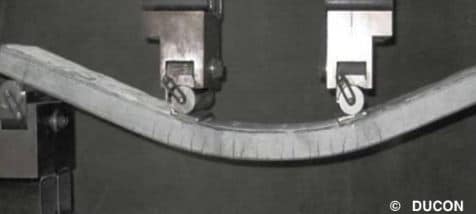

Ductility

The steel provides ductility to the reinforced concrete structures. The ductility in concrete shows the distress in cracking and deflection if the reinforced concrete having the overloading. This enables the engineers to consider engineers to save it from concrete damages.

Seismic Resistance

It is properly designed for reinforced concrete structures that are resistant to earthquakes.

Ease of Construction

As compared with the steel used in the structure, reinforced concrete requires less skilled labor for the erection of the structure.

Ability to consume and Recycle Waste

There are several industrial wastes and by-products like fly ash, slag known as GGBFS or ground granulated blast-furnaces slag, waste glass and like the ground, tires can be recycled as a substitute for cement or aggregate or supplementary materials. The concrete production reduces environmental impacts due to industrial waste and also improves the characteristics of concrete and consequently, the quality of the structure is not compromised.

The concrete can be recycled as aggregate for the use as sub-base material in roadbeds and parking lots, gabion walls as riprap to protect shorelines or in other applications or granular material with reducing the amount of material which is landfilled and need for virgin materials in new construction.

One of the main advantages of concrete is its ability to use different application methods. Concrete is also hand-applied, poured, pumped, sprayed, grouted and it is also used for application for shotcrete and tunnels.

Disadvantages of Reinforced Concrete

- The Reinforced concrete structures are heavier than others like steel, wood and glass structures.

- The usual concrete building needs massive formwork, centering, shuttering to be fixed which requires lots of site space and labor work.

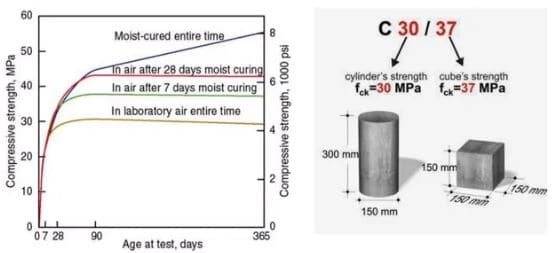

- Concrete requires time to attain its full strength. So, it is not used immediately after construction. The steel structures are ready to use.

- The main process of using reinforced concrete are mixing, casting and curing. Which all are affects the final strength.

- The price of the forms used for casting RC is high compared to other techniques.

- The shrinkage causes crack development and strength loss.

Applications of Reinforced Concrete

- Buildings

- Bridges

- Flyovers

- Water Tanks

- Roads

- Floating Structures

- Foundations

- Marine Structures

- Pipes and Conduits

- Precast Works

- Chimneys and Towers

- Retaining Walls

- Bunkers and Silos