Fly Ash Bricks In Indian Market

Before starting the discussion on fly ash bricks first, we have to look at the effect of red clay bricks on nature.

There is one estimate that around 180 billion tonnes of common burnt bricks are used per annum which means it required 340 tonnes of clay and it comes from the top layer of around 5000 acres of land dug out by brick manufacturers. The red clay brick is heated and required coal or wood which may the cause for deforestation.

What is fly ash brick in the Indian market

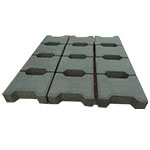

The pulverized fuel ash is generally known as fly ash and it is a by-product from the coal-based power plant. The fly ash brick manufacturer uses this ash to make the fly ash brick as the alternative of red clay bricks.

The demand for fly ash bricks in India is increasing. As the cost and environmental benefits, people prefer more and more fly ash bricks over common burnt bricks.

India depends on the coal-based power plant. These plants produce a very large amount of fly ash. The government has no other way to dump the fly ash and the fly ash is dangerous for the environment.

The fly ash brick making is a very profitable business in India as the brick quality is high and required less resource than common burnt bricks.

Important Factors That Required for Manufacture Fly Ash Bricks

First, it required a minimum half acre of land prefer 1 acre for storing and curing the bricks.

Second, choose the factory location in 100 km radius of the thermal power plant to get permission and quota of fly ash. For make fly ash brick required lots of water. So make sure that you have enough water supplies to continue the production.

One of the problems to make fly ash brick is to store fly ash. You could not store fly ash in open ground as it is harmful. So it is advisable to store in Silo.

To make fly ash bricks required approximately 30, 00,000 INR as working capital. This includes machinery and production capacity of 12,000 bricks per shift.

In growing India labor is the biggest problem and the fly ash brick making is not an easy task and somewhat dusty work. So attract the labors with high pay and incentives.

Benefits of Fly Ash Bricks

The profit factor is very high in the fly ash brick manufacturing. There is a minimum profit of 1 INR per brick is for sure. It may vary for different places and it depends on labour, raw materials and power supply.

As we know the fly ash is only available through the thermal power plant. So before starting business manufacturers have to research on demand for fly ash bricks and the availability of fly ash. It is advisable to get your quota of fly ash than to buy from the black market.

Machinery is a heart of any industry. So buy a machine from the well-established manufacturer. The reason behind is this machine required regular tune-ups and frequent maintenance in the starting of production. The rotary type hydraulic machine is highly recommended for primary manufacturers.