Fully Automatic Block Making Machine RT6B+

Today we will see RT6B+ machines and what machines are in the automation.

The RT6B+ is a fully automatic block making machine with automatic rack loading and unloading system.

RT6 model is developed as the budget solution to entrepreneurs interested in setting up the factory to manufacture concrete products in medium-size block plants.

The machine is developed to provide a system with indigenous curing solutions.

There is also the option of a rack loading and unloading system which has an automatic storage rack moving conveyor which reduces the delay and labour fatigue.

It has an automatic standard cubing system and blocks with 1.2 by 1.2 meters cubes.

There is An line palletizing of dry side and wet side handling which eliminates the involvement of labour in the plant.

The main feature is contactless product manufacturing and maintain

RT6B+ Process Flow Chart

There are two options Three bin feeder and Single Bin Feeder. After that raw material is transfer to automatic weigh batcher and dry mixes. We also provide a cement weigh batcher. Next water from the water dosing system, dry mixes, and cement sent to either Face Concrete Mixer or Base Concrete mixer. There are two options from Face Concrete Mixer and Base Concrete Mixer to choose from.

After mixing, the conveyor belt took the mixer to the RT6 machine. Here the blocks are press at different vibrant frequencies with the help of variable frequency drives. This high-frequency vibration gives the product better compaction, higher density, and maximum strength.

Now the conveyor belt takes the wet blocks to the rack loading device and stores them at the curing chamber. There is an automatic storage rack moving conveyor which stores wet blocks and sends dry blocks for packaging.

After drying, first, the rack unloading device moves the blocks to block arranging via dry block conveyor. There are two processes done here. First, the blocks picked up and sent to an automatic cuber, and empty pallets are sent back to the machine. The cuber makes the cub of the block and packed it.

Finally, the products are ready.

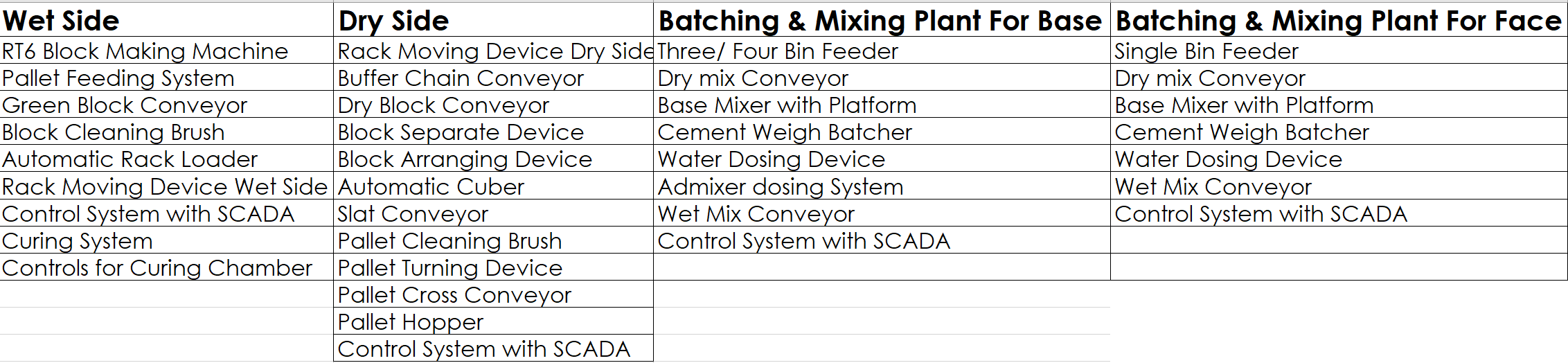

This is the List of Equipment of RT6B+

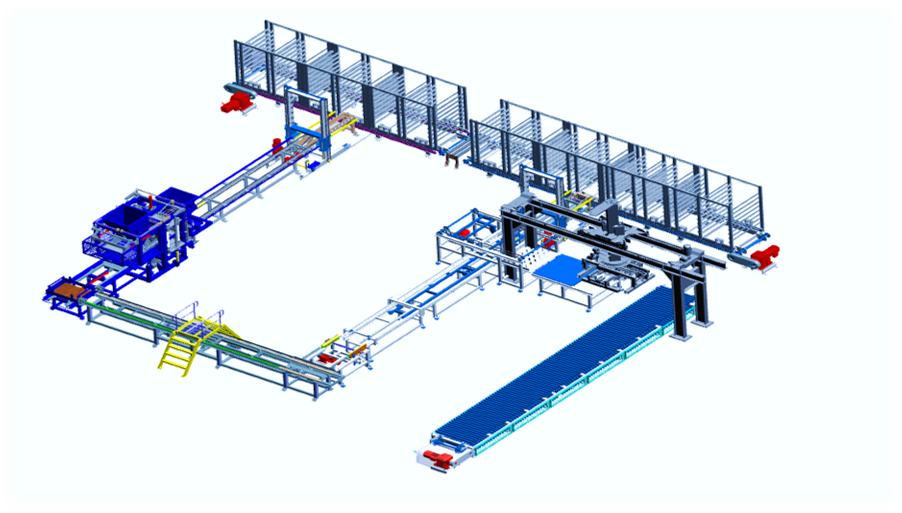

The general arrangement of the RT6B+ Type.

Machine installed at the site.

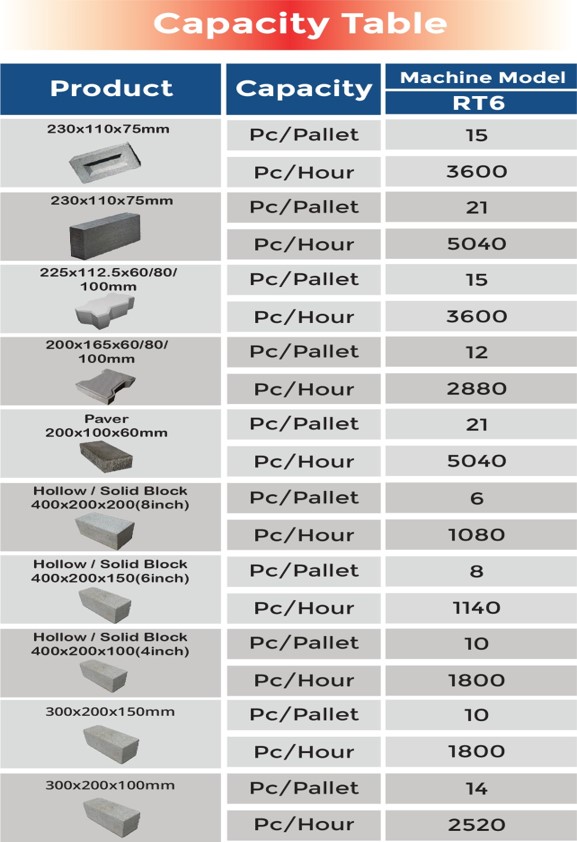

Here is the Production capacity of RT6B+.

Now understand the function of the main parts of the machine.

Automatic Rack Loader & Un-Loader Device

This device loads the rack after the pallet comes out from the block machine and rolled to be lift-off through the green conveyor.

In the same way after curing the racks are first moved out and placed where the unloading device is and it unloads the pallets from rack to loop line.

Both the Rack Loader and Un-Loader are automatic and PLC controlled.

Automatic Rack Moving Device for Wet and Dry Side

It places the rack in the position of loader and unloader. It is driven by chain and powered by SEW geared motors.

Dry Block Conveyor & Pallet Turning Device

The conveyor transports the pallets which are first unloaded by loader and places them in the block separate device and send them to the pallet turning device.

The pallet turning device turns the pallet and utilizes the pallet to use on both sides which gives long life to pallets and avoids bends and high pressure.

Block Separate Device and Block Arranging Device

The device arranges blocks as per even size for cuber clamping for pallet size of 900 x 700.

Automatic Cuber & Slat Conveyor

The cuber makes the cubes of the dry blocks and stacked on a slat conveyor.

It is PLC controlled and driven by a hydraulic system with an accumulator.

Hope this information will help you to choose the best one.