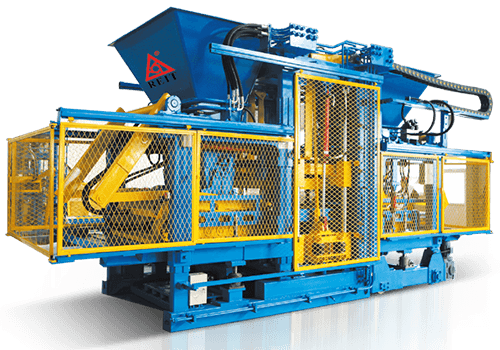

RT 6 Paver Concrete Block Machine Installed at Jaipur

Block Machine Installation In Progress At Jaipur, India

Fly ash bricks are made using the waste of thermal power plant. The ash of burnt coal is used as an input, thus reinforcing the idea of turning waste into wealth. In India itself, the annual generation of fly ash is expected to be around 200 million tones by end of the 12th five-year plan and around 500 million tones by 2032.

These are some advantages of using fly ash bricks that is making major construction houses, and for that matter, even the government, move towards it.

Q Green Techcon Pvt Ltd is working strongly towards creating a Green India and through our machines, we sought to promote Green Technology in Construction Industry and also provide people an opportunity to convert ‘Waste Into Wealth’. We have mastered the art of brick making successfully by manufacturing bricks and blocks using 70-80 % Fly ash.

For any fly ash brick machine, Inquiry Call Us Now: +91 97320 35946 or Mail Us: [email protected]

The Indian market is in a transformational change, majorly so in the construction sector, and we are forecasting that this trend will continue till at least 2022. It is the Government’s thrust and the increasing awareness and demand for fly ash bricks that has given stimuli to this sector. The Government, Corporate and even individual’s for that matter, have started seeing infrastructure as a stepping-stone for sustainable development. We have also noticed that the demand for fully automatic machines have grown manifolds and the reasons that can be attributed to this are, less concentration on labour, economical production, low wastage rate, etc. We are the leader in fully automatic machines, and hence, have seen a growth in demand from almost all parts of the country, South and West taking the lead.

The Government’s role in Green India and Infrastructure development cannot be overlooked. Swachh Bharat Abhiyaan and affordable housing scheme, have not only put fly ash bricks in a better position as compared to clay bricks but has also promoted sustainable and economic development. Our products fit perfectly with the Government’s vision.

Hence, what we have seen is that the market is becoming increasingly aware of the various products available and are opting majorly for machines that are green, feasible and strong. The infrastructure sector is being given a lot of importance and sustainable development is not far behind. This has proved to be extremely beneficial for us as it not only aligns with the fact that our products are green products but also with the fact that our machines lower cost of production, increase efficiency and make products worthy of forming the foundation on which the nation can be built.

For supporting green and clean India Q Green Techcon manufactures a wide range of fly ash bricks machine and concrete brick machine. For Buying this machine check qgreentech.com

For any fly ash brick machine, Inquiry Call Us Now: +91 97320 35946 or Mail Us: [email protected]

REIT Q Green Machine PVT. LTD. Successfully Install New RT6 Paver Block Making Machine At Bangalore.

For Full Information About Machine Visit Here: RT6 Paver Block Machine

Every customer, at some point, will have this question. What is the added advantage of manufacturing in India and why should they opt for a paver block making machine that is produced in India and not elsewhere. With our personal experience, we would like to tell you that it not only helps you save on cost and time but also facilitate in improving the longevity of the machine.

Firstly, buying a machine that is made in India allows you to save time. Initially, it took us about 3 months to import and deliver RT6 the paver block making machine, one of our star machines. Now we have reduced the delivery schedule from 3 months to just 1 month.

Secondly, you save on costs. Since the block making machine is manufactured in the country itself, you save yourself the additional duties and taxes that are levied on imports.

The most important advantage remains, easy availability of spare parts. Initially, the electrical spare parts were not available locally and hence maintenance took undue time. This problem was solved as soon as we started producing the machines in the country.

Further, the paver block making machine can be molded to suit the market needs. We have customized and further developed the machines to suit the customer requirements. We have introduced components like gearbox (from SEW), motors (from ABB) and top quality electric parts (from Schneider). This increases the utility of the product and makes it the best in the market and has also allowed us to strictly meet the International and Indian Standards without compromising on the benefits.

Hence machines produced in the domestic market enable the customer to save on cost and time and increase the efficiency of the machine by facilitating quick maintenance.

If you searching for paver making machines then you can check our paver block machine products.

For any fly ash brick machine, Inquiry Call Us Now: +91 97320 35946 or Mail Us: [email protected]